Unsere Favoriten

Unsere Mission

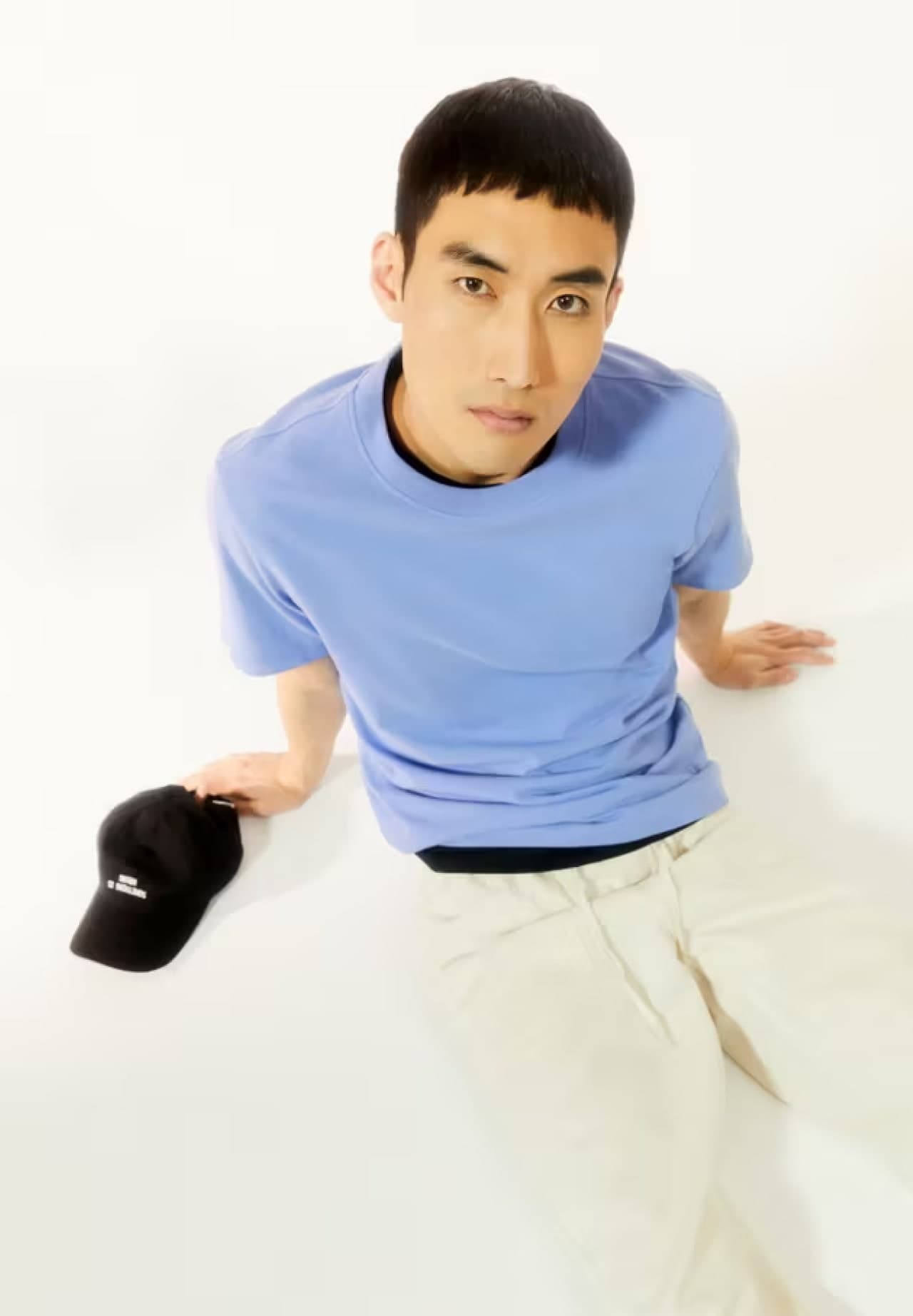

Made to make a difference

Unsere Mission ist einfach: Produkte herstellen, die Menschen lieben und die am wenigsten schädlich für den Planeten sind und Menschen befähigen ihren Lebensstil zu verändern, um dem Klimawandel entgegenzuwirken.